Why Choose Us

Discover why leading companies in defense, medical, and aerospace industries trust Shenzhen Yujiaxin Technology for their critical component needs.

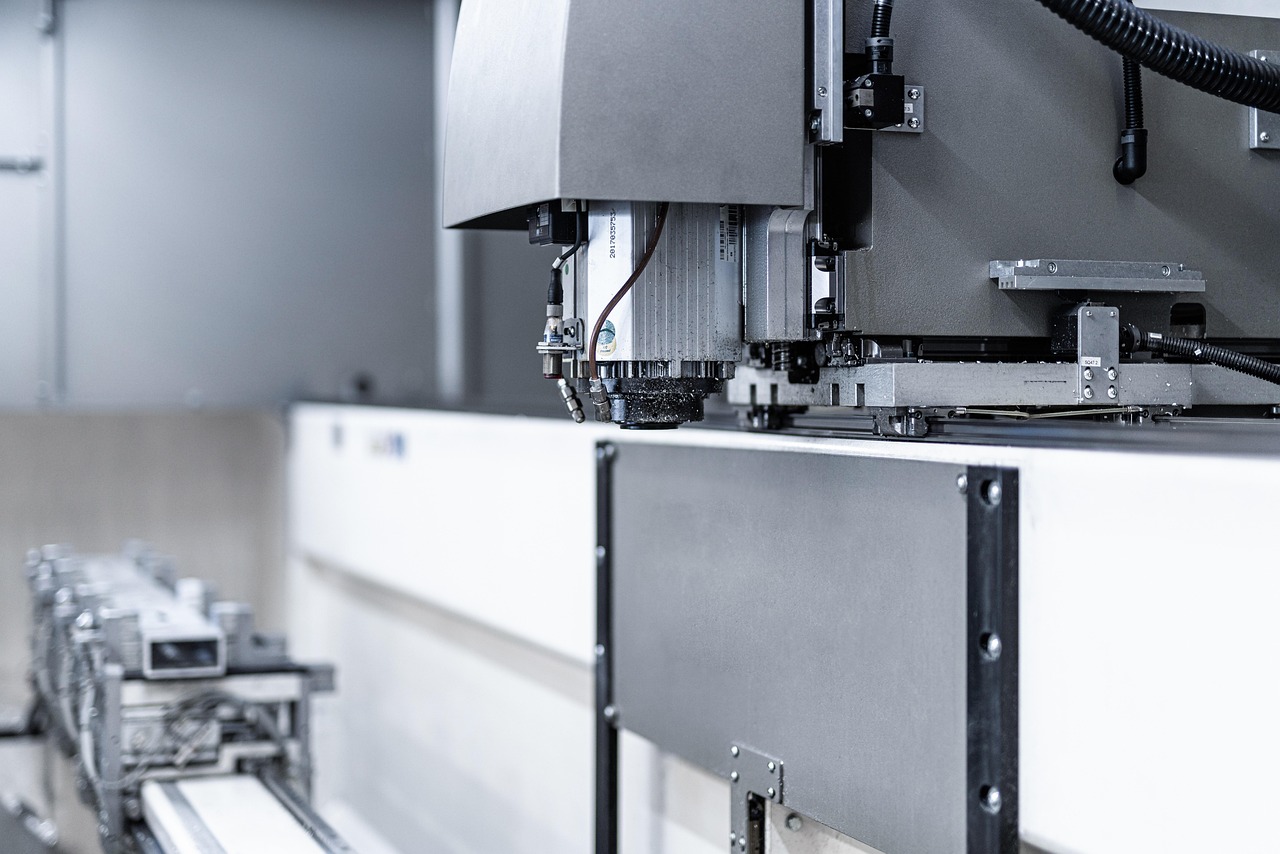

Ultra-Precision Machining

Our advanced CNC machining capabilities allow us to produce components with tolerances as tight as ±0.001mm, meeting the most stringent requirements of defense and medical applications.

Quality Assurance

We adhere to ISO 9001:2015 and AS9100 quality standards with comprehensive inspection protocols, including CMM, optical comparators, and surface roughness testers.

Military & Defense Expertise

With years of experience serving defense contractors, we understand the critical nature of military components and maintain strict confidentiality and security protocols.

Medical Grade Components

We specialize in biocompatible materials and ultra-clean manufacturing processes for surgical instruments, implants, and diagnostic equipment.

Advanced Material Capabilities

Expertise in machining exotic alloys including titanium, Inconel, stainless steels, and specialized composites for extreme environments.

Dedicated Engineering Support

Our engineering team partners with you from design through production to optimize manufacturability, reduce costs, and ensure performance.

Who are we

Leading Manufacturer of Precision Metal Parts

Shenzhen Yujiaxin Tech. Co., Ltd. are a leading manufacturer of precision metal parts in China, serving the consumer electronics, automotive, medical, and industrial sectors. Our team of experts uses the latest technology to ensure that every product we deliver is of the highest quality and meets the client’s specific needs. With our years of experience, we have established a reputation for excellence in the industry.

Custom Metal Parts Ordering Process

WORKING WITH US IS SIMPLE.

1.Design Submission

Provide technical drawings (DWG, DXF, PDF, STEP, IGES)/samples + key specs (material, tolerance, surface treatment, quantity).

2.Quotation Review

Manufacturer evaluates feasibility and returns a detailed quote with unit cost, MOQ, and lead time.

3.Production Approval

Confirm final design adjustments (if any) and authorize production.

4.Quality Assurance & Delivery

Parts undergo dimensional inspection (with factory inspection reports) and are shipped with certifications (e.g., material test reports).

Ready to Start Your Project?

Contact us today to discuss your precision machining requirements. Our engineering team is ready to provide solutions for your most challenging components.